- #Kepware system requirements drivers#

- #Kepware system requirements software#

- #Kepware system requirements Pc#

- #Kepware system requirements windows 7#

When installed on a 64-bit operating system, the application runs in a subsystem of Windows called WOW64 (Windows-on-Windows 64 bit).Windows XP Professional (Service Pack 3).Windows Server 2003 (Service Pack 2), R2 (32 bit).Windows Vista Business, Enterprise, and Ultimate (32 bit and 64 bit).

#Kepware system requirements windows 7#

Windows 7 Professional, Enterprise, and Ultimate (32 bit and 64 bit).Review requirements and implement the TOP Server configuration and train. This application supports the following Microsoft Windows operating systems: Whether you are the end user, a system integrator with many tasks and not.

#Kepware system requirements Pc#

These requirements must be met for the application to operate as designed. KEPServer requires an IBM PC or compatible with a Pentium class microprocessor, with 16 MB of RAM minimum, 4MB of free hard disk space.

#Kepware system requirements software#

Security … KEPServerEX includes a variety of tools that control user access to the server, data source, or data values, regulate read/write access, provide the ability to disconnect client applications, and support the configuration of secure data tunnels.The server has minimum system requirements for both software and hardware. #Kepware system requirements drivers#

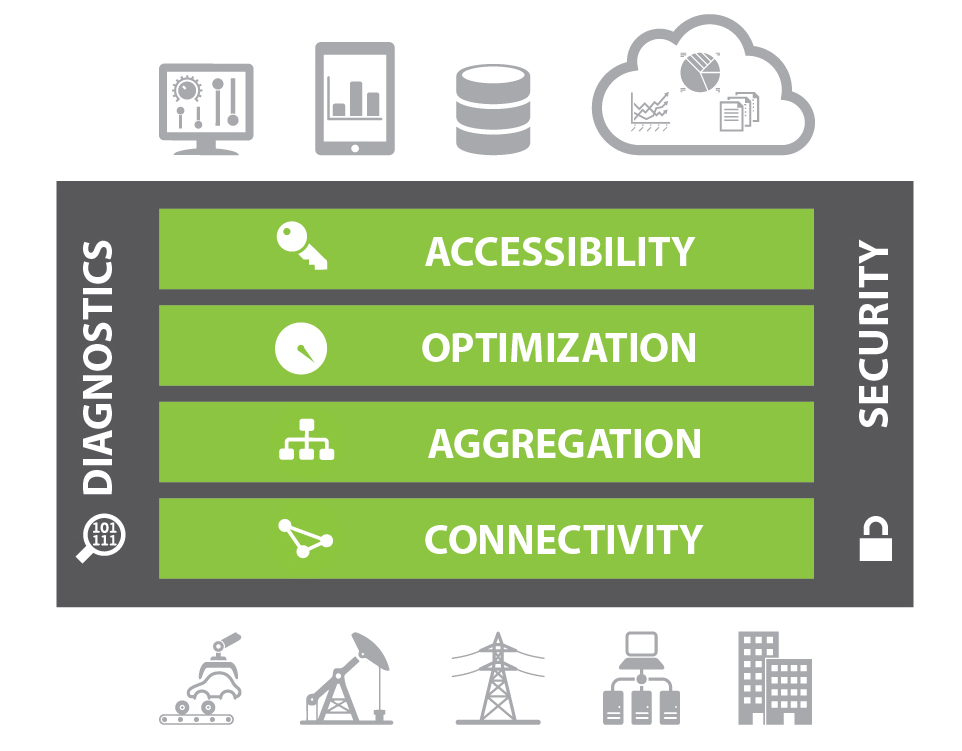

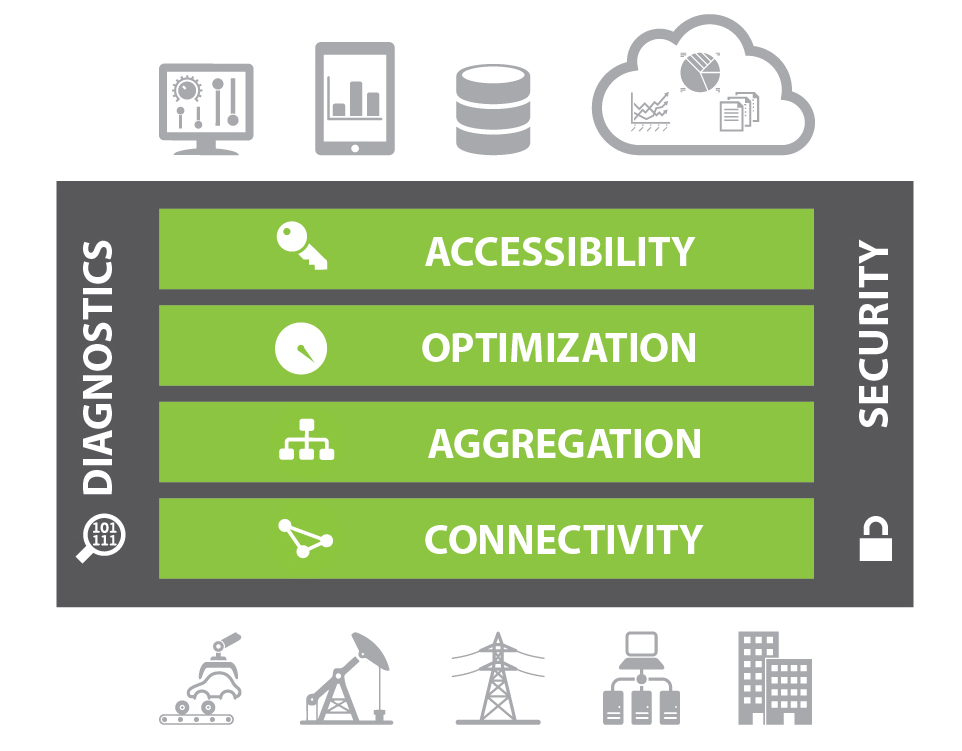

Connectivity … KEPServerEX supports the broadest range of drivers available, including current and legacy devices across various verticals, a variety of wired and wireless network mediums, and connectivity to databases, custom software applications, and other OPC servers. Aggregation … KEPServerEX simplifies the configuration of connected applications by providing a single point of entry to all information-eliminating the need to purchase, operate, troubleshoot, and maintain multiple disparate solutions for discrete connectivity. KEPServerEX to meet the connectivity requirements of a specific device, system, or other data source.  Optimization … KEPServerEX optimizes communications and reduces network and device load via data conditioning and reduction, customized load balancing, and protocol-specific communications optimization. Kepware drivers are software components that enable. Michael Kalbe, Auria Solutions GmbH In the past, orders for the production lines were entered in the SAP® system and manually transferred to an Excel list. Electronic Approval and Audit Trail for devices and documents. Accessibility … KEPServerEX provides access to client applications (like MES and SCADA) and IoT and Big Data analytics software via OPC, proprietary protocols (including GE NIO, SuiteLink/FastDDE, and Splunk), IT protocols (including MQTT, REST, ODBC, and SNMP), and flow measurement export to common Oil & Gas industry and customized formats. In projects like these, we created an integrated system for industry 4.0 with inray, which we can flexibly adapt and supplement as required. AutoSave provides complete control over device programs, including: Detailed comparison of any two versions of a program. KEPServerEX provides the industrial connectivity, usability, and performance required by the enterprise-offering competitive benefits that can be experience from the plant floor to IT to the boardroom. The platform is developed and tested to meet our customers’ performance, reliability, and ease-of-use requirements. KEPServerEX leverages OPC (the automation industry’s standard for interoperability) and IT-centric communication protocols (such as SNMP, ODBC, and web services) to provide users with a single source for industrial data. drivers, client drivers, and advanced options to fit your unique industrial control system requirements. The platform design allows users to connect, manage, monitor, and control diverse automation devices and software applications through one intuitive user interface. Kepwares KEPServerEX communications platform. KEPServerEX is the industry’s leading connectivity platform that provides a single source of industrial automation data to all of your applications. Kepware’s KEPServerEX Connects disparate devices and applications, from plant control systems to enterprise information systems

Optimization … KEPServerEX optimizes communications and reduces network and device load via data conditioning and reduction, customized load balancing, and protocol-specific communications optimization. Kepware drivers are software components that enable. Michael Kalbe, Auria Solutions GmbH In the past, orders for the production lines were entered in the SAP® system and manually transferred to an Excel list. Electronic Approval and Audit Trail for devices and documents. Accessibility … KEPServerEX provides access to client applications (like MES and SCADA) and IoT and Big Data analytics software via OPC, proprietary protocols (including GE NIO, SuiteLink/FastDDE, and Splunk), IT protocols (including MQTT, REST, ODBC, and SNMP), and flow measurement export to common Oil & Gas industry and customized formats. In projects like these, we created an integrated system for industry 4.0 with inray, which we can flexibly adapt and supplement as required. AutoSave provides complete control over device programs, including: Detailed comparison of any two versions of a program. KEPServerEX provides the industrial connectivity, usability, and performance required by the enterprise-offering competitive benefits that can be experience from the plant floor to IT to the boardroom. The platform is developed and tested to meet our customers’ performance, reliability, and ease-of-use requirements. KEPServerEX leverages OPC (the automation industry’s standard for interoperability) and IT-centric communication protocols (such as SNMP, ODBC, and web services) to provide users with a single source for industrial data. drivers, client drivers, and advanced options to fit your unique industrial control system requirements. The platform design allows users to connect, manage, monitor, and control diverse automation devices and software applications through one intuitive user interface. Kepwares KEPServerEX communications platform. KEPServerEX is the industry’s leading connectivity platform that provides a single source of industrial automation data to all of your applications. Kepware’s KEPServerEX Connects disparate devices and applications, from plant control systems to enterprise information systems

0 kommentar(er)

0 kommentar(er)